Molded Case Circuit Breaker or MCCB | How They Work

What are Molded Case Circuit Breakers?

Molded case circuit breakers, also known as MCBs, are a type of electrical protection device that is used to automatically turn off electric circuits when excess current flows through them.

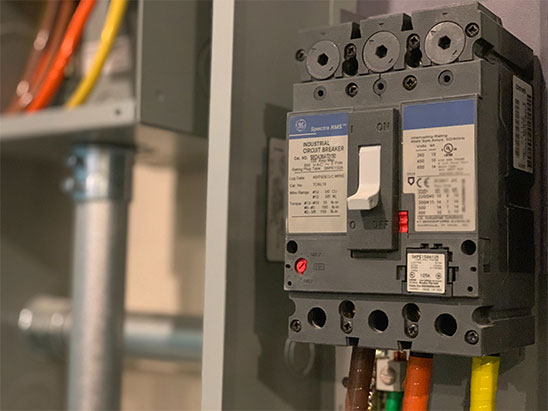

MCCB Design and Components

MCBs consist of both mechanical and electrical components (thermal and magnetic) encased in a molded insulating material such as plastic or porcelain. This molded case gives them their name and provides protection against electric shocks and environmental contaminants.

The main components inside an MCB are:

- A current carrying conductor

- A tripping mechanism

- An arc extinguishing chamber

- Auxiliary contacts and alarm switches

When excess electricity flows through the breaker, a mechanism automatically triggers the contacts to open or "break" the circuit. This prevents damage from overloads and shorts. An arc chute inside extinguishes the arc produced from breaking the electrical circuit.

Advantages of MCCBs

Molded case circuit breakers provide several key advantages:

- Compact size - MCBs are smaller than other breaker types.

- Fast reaction - They can trip quickly, in as fast as a few milliseconds.

- Adjustable - Some MCBs allow users to set desired trip current levels.

- Easy to reset - Simply flipping the switch restores power.

- Protection - Prevent fires and damage by interrupting overloads.

- Affordable - MCBs are an economical type of circuit protection.

These benefits make molded case breakers a popular choice for residential, commercial, and industrial electrical systems.

MCCB Applications

Common applications for molded case breakers include:

- Power distribution boards

- Motor control centers

- Industrial machine tools and robotic cells

- HVAC equipment

- Appliances

- Commercial lighting fixtures

- Generators

They provide reliable overload and circuit protection for both power and lighting branch circuits ranging from 15 to 125 amps. Different frame sizes are available for any installation environment.

MCCB Specifications and Rating

Molded case circuit breakers have published specifications that users reference to select the properly rated unit:

- Voltage rating - Compatible voltage such as 240V or 480V.

- Interrupting rating - Maximum short circuit current handled.

- Trip curve type - Response time characteristics.

- Number of poles - Single or multi-pole configurations.

- Amp frame size - Designed mechanism for protection and isolation.

Additional considerations are altitude, temperature extremes, and any applicable compliance standards. Always consult technical datasheets when choosing MCBs.

Common MCCB Industry Brands Eaton and More

- Eaton CH Series

- Schneider NSX

- GE Spectra Series

- Siemens WL Circuit Breakers

These major manufacturers provide reliable, certified products tested to global standards within the industry.

MCCB Protection Features

Many modern molded case breakers now integrate supplemental features used to protect the electrical circuit:

- Ground fault - Detect dangerous leakage electricity.

- Arc fault detection - Recognize hazardous arcing signatures.

- Zone selective interlocking - Cascade tripping sequence.

This expands safety and coordination while minimizing downtime. Communicating circuit breakers are also emerging with network connectivity.

How to Select an MCCB

Follow these key steps when specifying and purchasing molded case circuit breakers for reliability:

- Determine correct frame size by checking equipment nameplates for full load amps or MCA.

- Choose suitable voltage, poles, and interrupt rating.

- Define necessary response time and fault curve characteristics.

- Consider any needed supplemental protection features.

- Reference manufacturer breaker catalogs and published datasheets.

- Ensure regulatory and standards compliance.

- Order from reputable suppliers to avoid counterfeit products.

This process helps identify the optimal molded case breaker for the application.

MCCB Testing and Maintenance

Routine molded case circuit breaker care involves:

- Testing function per manufacturer guidance.

- Cleaning debris and dust buildup.

- Checking wiring terminations are secure.

- Verifying tightness of any bolted connections.

- Monitoring contact wear with resistance tests.

- Recording exercise data to identify aging breakers.

Periodic inspection and testing ensures trouble-free MCB protection.

Frequently Asked Questions

Here are answers to common questions about molded case circuit breakers:

How do MCBs detect overloads?

Bimetallic strips or electronic solenoids sense excess temperature rise from overload currents. This activates the overload or short circuit mechanism.

What is the difference between MCBs and MCCBs?

MCBs are used for smaller branch circuits, while MCCBs (molded case circuit breakers) handle higher electricity associated with distribution circuits.

Why choose MCBs over fuses?

MCCBs can also be easily reset, while fuses require replacement. This provides convenience while avoiding downtime.

What causes nuisance tripping of MCBs?

Loose connections, oversized breaker ratings, frequent surges, and load harmonics can cause unwanted MCB faulting.

Are MCBs reusable after interruption?

Yes, the range of molded case breakers available are designed for repeated interruption and resetting throughout their product lifetime.